For projects like pipelines, highways, urban roadways, and railways, conventional surveying can be tedious. Boots on the ground can pose a serious challenge for crews to acquire precise measurements efficiently and safely—taking a lot of time, interrupting day-to-day traffic, and calling for large crews to get the job done. While there’s a time and a place for traditional surveying (we should know since it’s what we love to do!), GeoVerra embraces technology to advance our industry and yours.

Sometimes, it means giving our boots a break!

New Standards

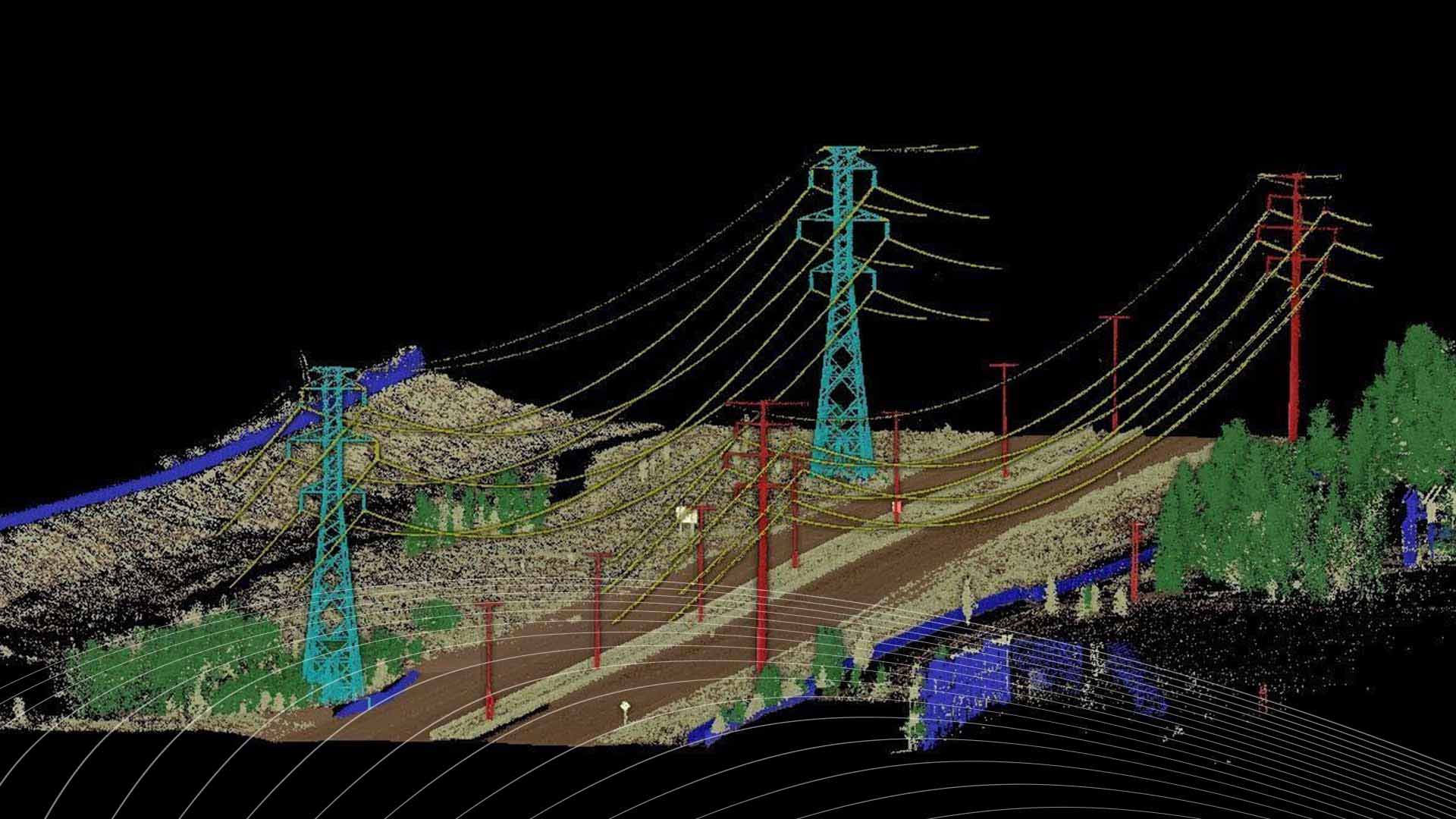

Mobile Mapping Systems, or MMS, is an advanced laser affixed to a moving vehicle that scans its surroundings 360 degrees. This technology measures objects by millions of points per second with centimetre accuracy, quickly collecting every visual component in diverse environments including highways, urban streets, railways, and pipeline routes. Clients can easily access this new class of data digitally, for a total immersive and accurate 3D view of objects and surroundings for their project.

Technology is redefining the business of road, railway and pipeline projects and radically changing the way our clients think about surveying. With improved safety, compressed schedules, and reduced costs for some of the country’s largest infrastructure and transportation projects, MMS is our standard for collecting spatial data. In fact, GeoVerra’s teams were one of the first to adopt mobile mapping technology.

Alex Garcia, GeoVerra project manager, relies on MMS for the major projects he handles. “The system collects the imagery and what we call ‘point cloud,’” he says. “That means the laser is spinning and collecting tiny dots that are literally three millimetres apart from each other. We take accuracy to the next level!”

The MMS Makeover

Many GeoVerra clients focus on road design—requiring knowledge of surface, structures, culverts, powerline locations, and more.

“Before MMS, it looked like this: the team assembles to the site and physically walks all day to collect data for only one of those components. If more information was needed, say specific powerline data, then the team would reassemble again for another day in the field, collect the information, and take it back to the office,” explains Garcia. “With mobile, it’s simple: the surveyor drives down the road, collecting 360 degree point cloud and images,” says Garcia. “From surface condition, curbs, manholes, powerlines and whatever else the client needs, we can collect everything with high precision—and it’s accomplished literally in a day!”

In fact, Garcia’s team collected 350 kilometres’ worth of data for a client—with centimetres’ accuracy—in one day. That same result would require more than three months of boots-on-the-ground collection by a team of surveyors! On large infrastructure projects, meeting or exceeding schedule expectations is critical.

Of course, increasing productivity at the expense of safety is not an option. Says Garcia, “In the traditional method, we would have to shut down highways or work off the side of the road where safety is a huge concern. We don’t have to do that anymore.”

MMS addresses another common issue that isn’t necessarily top of mind for everyone, but surveyors have heard plenty: “Often during road construction, clients tell us a resident has come forward and said, ‘Your construction damaged my property,’” explains Garcia. “With imagery by way of this technology—done before and after the project—the client can say no, I have proof that your house had this issue before. Our clients really enjoy that!”

More information, more accuracy, more safety—all while saving manpower and money. Think MMS can boost your next project? Contact GeoVerra today: www.geoverra.com/contact